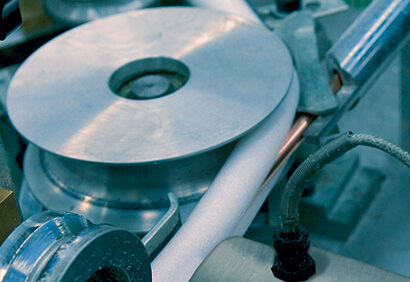

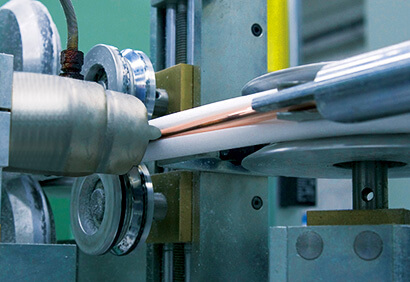

ISOCLIMA’s prerogative is the production of all the insulating sheaths that are used for the coating of copper pipes. The completeness of its production programme and the quality of its products satisfy even the most demanding of customers and puts ISOCLIMA among the major companies in the industry.

ISOCLIMA’s production cycle has always been based on an accurate Quality Management System and the strict application of standardised procedures; in doing so, the company easily passed all of the ISO 9002 certification levels.

Sealing of the sheath and external finishing of the product are continually monitored so as to ensure consistent appearance and efficiency of the finished product.

The care and attention paid to even the smallest of details contributed to put the ISOCLIMA products among the ones most demanded by final users.

Array

(

[p1] => cicli-di-lavorazione

[p2] => azienda

)